Confirming Quality

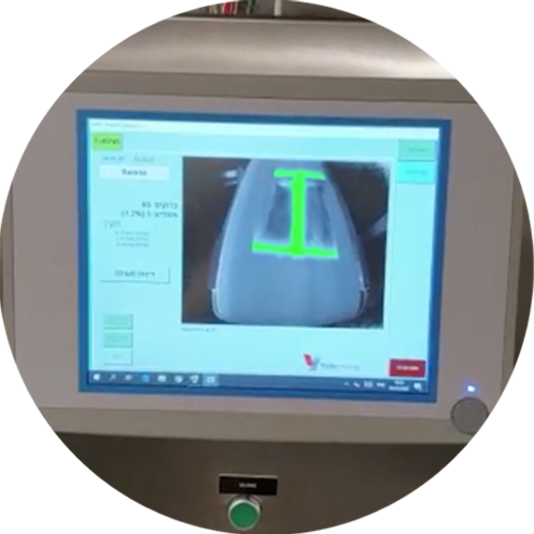

Communicating Data

Creating Efficency

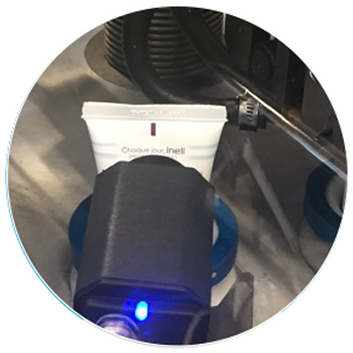

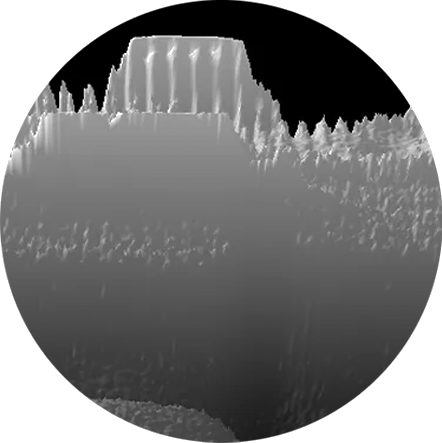

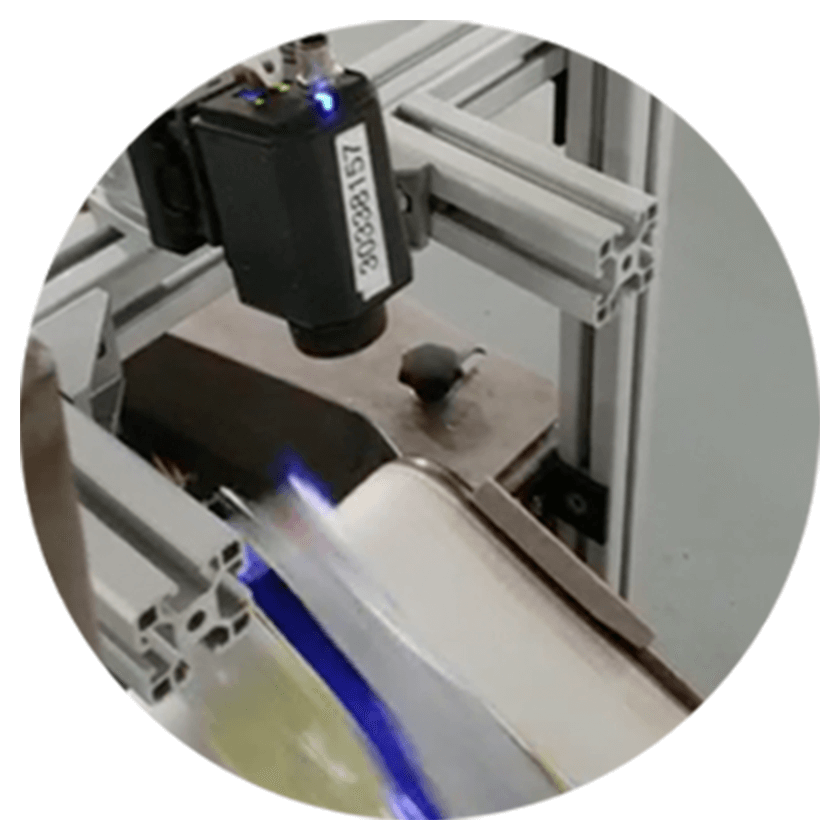

Yoran Imaging utilizes award-winning breakthrough thermal imaging technology to revolutionize the filling and heat-sealing process on packaging lines in a range of consumer facing industries.

Learn More

Drawing upon more than two decades of thermal imaging inspection experience, our solutions provide non-invasive, 100% in-line inspection combined with production-optimizing data collection and analysis.

Our groundbreaking Process Analytical Monitoring System:

Replaces inadequate manual sampling with comprehensive product inspection.

Provides unprecedented levels of packaging line insight.

Preempts production failures before they occur.

The result?

Dramatically heightened brand protection.

Smarter manufacturing processes.

More efficient packaging operations.

We create data, so you can control your process.

The Problem

Imprecise inspection via random sampling has long been the norm on high-speed packaging lines, where vital aspects of filling and heat-sealing procedures are seldom monitored and harnessed leading to substantial downtime and increased product waste.

The Solution

Eliminate manual, periodic sampling and inspect every single heat-sealed product before it leaves the production line.

Learn More

Applications

Trusted by Global Leaders

Recognized by Respected Associations

Events

No events are found.